Dry Ice Cleaning Service for Heat Exchanger Tubes

Dry Ice Cleaning Service for Heat Exchanger Tubes

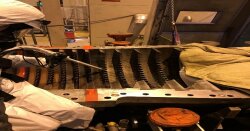

Welcome to our dry ice cleaning service, specializing in the cleaning of aluminum finned tubes commonly found in heat exchangers. Utilizing advanced dry ice blasting techniques, we provide efficient and non-destructive cleaning solutions ideal for preserving delicate aluminum surfaces while ensuring optimal heat transfer efficiency.

Dry ice blasting eliminates the need for time-consuming manual cleaning methods, such as scraping or using abrasive chemicals, reducing overall cleaning time for heat exchanger tubes.

Unlike traditional cleaning methods, dry ice blasting is non-abrasive and non-destructive, making it ideal for cleaning delicate aluminum surfaces of finned tubes.

Dry ice blasting produces no secondary waste, eliminating the need for disposal of hazardous materials and reducing environmental impact.

By minimizing the use of hazardous chemicals and eliminating manual labor-intensive cleaning processes, dry ice blasting enhances worker safety during heat exchanger tube maintenance.

Dry ice blasting is not limited to heat exchanger tubes; it can also benefit various other equipment and industrial applications, including Fin Fan cooler heat exchangers, Unit GT rotor (stator, rotor blades, buckets installation areas), compressor and turbine casings upper & lower halves, inlet bellmouth, generator rotor, and generator stators.

Dry ice cleaning perfectly addresses challenges faced in cleaning the outer surface of Fin Fan cooler heat exchangers. Traditional methods like high-pressure water can risk bending aluminum fin-fan ribs and may lead to a loss in cleaning efficiency.

Dry ice cleaning minimizes post-cleanup requirements as there is no wastewater produced, unlike steam cleaning or chemical methods.

Dry ice blasting leaves no grit or dust behind, ensuring thorough cleaning while being as effective as abrasive sandblasting.

Some machinery can be cleaned online or with minimal downtime using dry ice cleaning methods, eliminating expenses associated with the disposal of residue and reducing overall cleaning costs.

Our dry ice cleaning service for aluminum finned tubes offers a cost-effective, efficient, and non-destructive solution for maintaining optimal performance. With benefits including reduced cleaning time, preservation of delicate aluminum surfaces, and versatile applications across various industries, dry ice blasting is the superior choice for heat exchanger tube maintenance.

For inquiries or to schedule a cleaning service, please contact us now.