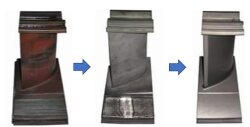

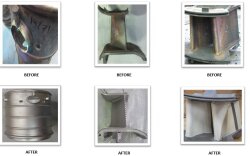

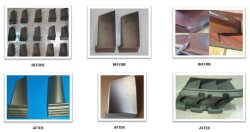

Parts refurbishment

Parts refurbishment

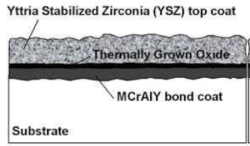

Thermal Barrier Coatings

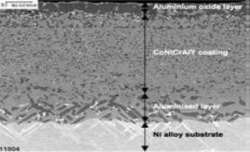

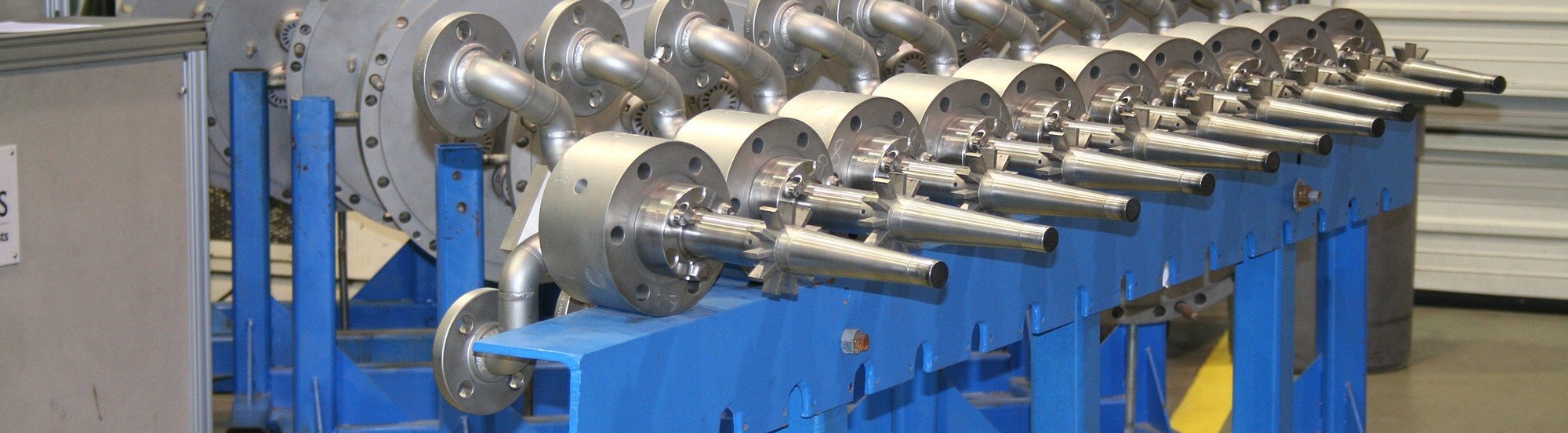

At Global Energy Service Industry, we specialize in providing advanced Thermal Barrier Coatings (TBC) for gas turbine capital parts, ensuring enhanced durability and performance in demanding operating environments. Our expertise extends to the application of MCrAlY coatings (where M represents Co, Ni, or Co/Ni), which are extensively utilized on first and second-stage turbine blades and nozzle guide vanes

Key Features:

Specialized TBC Coatings: Our Thermal Barrier Coatings are meticulously engineered to withstand high temperatures and harsh conditions, offering superior protection to critical turbine components

MCrAlY Coatings: We offer a range of MCrAlY coatings tailored to specific turbine applications, including Cobalt, Nickel, Chromium, and Aluminum compositions. These coatings provide excellent oxidation and corrosion resistance, prolonging the lifespan of turbine blades and vanes

CoNiCrAlY Thermal Spray Powders: Our portfolio includes CoNiCrAlY thermal spray powders, which feature a combination of Cobalt, Nickel, Chromium, Aluminum, and Yttrium. These powders are applied using advanced thermal spray techniques to create durable and resilient coatings on turbine components

By leveraging our expertise in Thermal Barrier Coatings, we ensure the reliability, longevity, and optimal performance of gas turbine capital parts. Contact us today to learn more about our TBC solutions and how they can benefit your operations