Spiral Wound Gaskets

Spiral Wound Gaskets

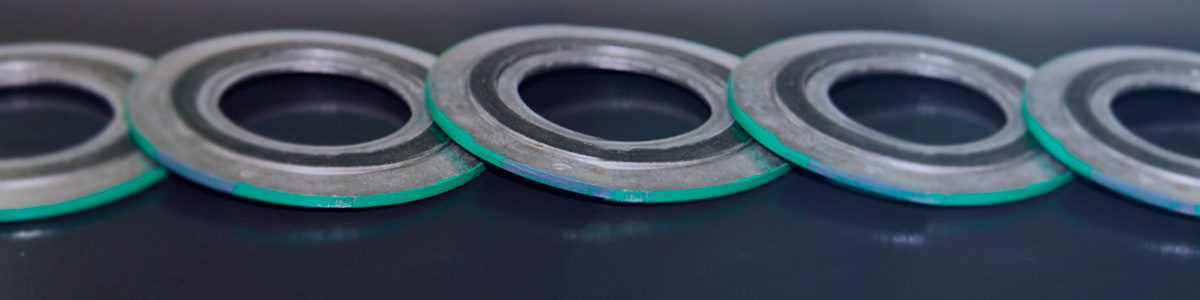

Spiral Wound Gasket

Spiral wound gaskets have the ability to recover under the action of fluctuating loads caused by process fluid pressure and temperature changes, flange face temperature variations, flange rotation, boltstress relaxation and creep.

The gasket sealing element consists of a pre-formed metallic windingstrip with layers of a softer, more compressible sealing material whichduring compression, is compressed and flows to fill imperfections in theflange surfaces when the gasket is seated. The metal strip holds thefiller giving the gasket mechanical resistance and resilience.

Spiral wound gasket’s basic sealing element,several layers of specially formed continuous V-shaped metal strip are spirally wound with alternate plies of soft filler strip. The “V” profile allows the gasketto act as a spring and the depth is carefully controlled to bestow the sealingelement with the best compression and recovery characteristics. In order tofurther enhance themechanical and sealing properties of the gasket, it isnormal practice to apply several layers of the metal strip only to the innerand outer diameters.

Controlled winding through machines are carefully monitor and adjust thetension of the winding strips. A uniform density throughout the productis produced. This provides the spring-like action within the gasket whichenables it to maintain a seal even when subject to fluctuating compressiveloads.

Type CGI (Gasket with Centering Ring & Inner Ring)

· Solid metallic inner & outer ring

· Suitable for high pressure and temperature applications

· Standard spiral wound gasket for raised face applications

· Prevents turbulence and erosion damage to flange

· Prevents damage to the gasket bore and inner windings

· Inner ring acts as a heat shield and as a corrosion barrier

· Wide choice of materials for filler and metal strip

· General and critical duties

Type CG (Gasket with Centering Ring)

· Solid metallic outer ring used as a centering deviceand compression stop

· Used mainly on raised face and flat face flanges

· Wide choice of materials for filler and metal strip

· General duties

Type GI (Gasket with Inner Ring)

· Solid metallic inner ring

· High pressure & high temperature capability

· Male to female flanges in vessels, valves and pumps

· Wide choice of materials for filler and metal strip

· General and critical duties

Type G (Gasket only)

· Wide choice of materials for filler and metallic strip

· Suitable for high pressure and temperatureapplications

· Recommended flanges are tongue & groove, male to female and flat face to recess in vessels, valves andpumps

· General and critical duties